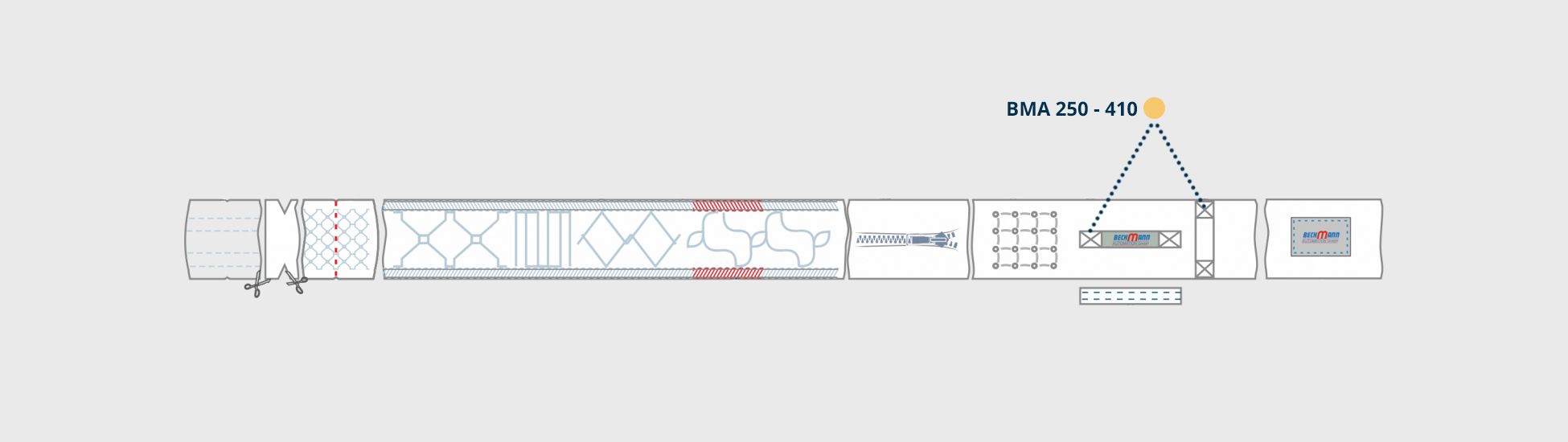

Both handle setting versions in one machine.Attaches 4 handles in one minute, with nearly no dimension tolerances. Beside to the high quality components we created a highly intelligent software which makes sure that you have an effective and smooth production. Our unique correction factor calculates the stretch of the border material to always have perfect dimensions. As soon as all your needed models are saved in our touch terminal, you just have to select the model and the quantity you want to produce. This causes that operators can operate the machine within 1 hour of training.

CE certificate. Dewinder system for border material.

Motorized pre dewinder to have no tension on the material input.

Centric border width adjustment.

Touch terminal. PROFI folding station.

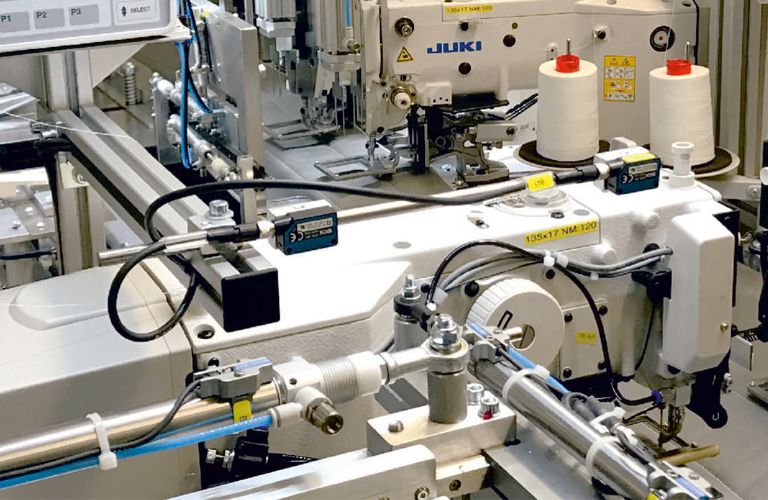

Extractable sewing heads for mainternance.

Border connection system to keep the waste material as low as possible.

Thread break detector. Detection material end.

Optional marking system. Optional eyelet setter.

Optional camera system for handles with embroidery.

Optional rest lenght control. Optional label setter (sewing seam on one side).

Optional handle magazin for pre cut handles.

Optional as 4 head machine for doubled capacity.

Model: BMA/250-410-PROFI

Sewing head: 4 Juki LK 1920

Border width vertical handles: 140-350 mm

Border width horizontal handles: 60-260 mm

Capacity: 1 border/min

Dimension: 2.800*2.200 mm

Power: 400V/16A/50Hz

Air: 8 Bar